MES Achieves Lead Times Beyond Expectations

- Aluminum Die Casting – weight of the part: 12.37 kg

- Press Used: 1600 T

- Tool Weight – 8,300 Kg

- Tool Kickoff to PPAP Parts Ready to Ship – 55 days

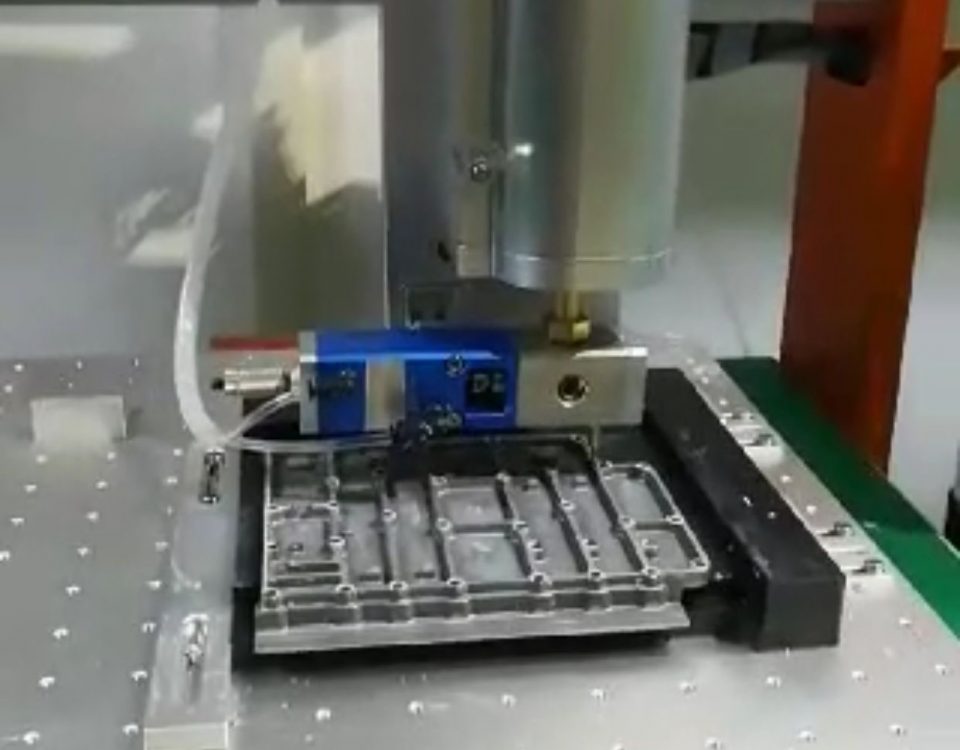

Last month, MES’ sourcing team was faced with yet another challenge for the outdoor lighting industry: delivering in record times an aluminum die casting tool of significant size: 1,240 mm x 1,075 mm x 895 mm weighing – 8,300 kg.

Mobilizing the Sourcing Manager in China and engaging our most trusted suppliers, MES was able to finish the tooling in 55 days. PPAP parts were sent two weeks later, and the heat sink parts were in production 10 days after PPAP approval.

Because of the relatively low volume (5,000), the size and complexity of the part, American suppliers quoted an average of 20 weeks lead time at 3 times the price achieved by MES.

At MES, we consider that the lighting industry is the one keeping us on our feet. Unlike automotive programs which take years to kick-off, lighting is extremely fast with short product lifecycles and frequent product introductions. The lead times from design to project kick-off can be counted in weeks while the quality demands are higher than anywhere else due to the weight given to the visual defects. We like to say that if we can make it in lighting we can make it anywhere.

MES is the preferred supplier of the largest names in lighting including but not limited to: Acuity Brands, Eaton Lighting, Hubbell, Schneider Electric.