Case Study – CB50100

Name of part: CB50100

Industry application: Lamp base

Commodity:

Material: A380

Process: Die casting

Weight of the part: 0.18kg

Lead time to quote: 3 days

Tooling

Size of tool:180*165*35

Weight of tool:6.4T

Lead time for tooling: 45 Day

Engineering issues (if any): Bent parts

PPAP lead time: 25 days

Production

Press used:420T

Finishing: None

Lead time to production: 10 days

Total lead time (factory to client): 25 days

Quality actions undertaken:

Root Cause

Die casting processing take out the parts leads to Pin position deformation when the parts after demoulding die-casting operator is not completely sprayed release agent onto the surface of the product Die-casting operator not skilled master mold discharging agent technique

Permanent Countermeasure

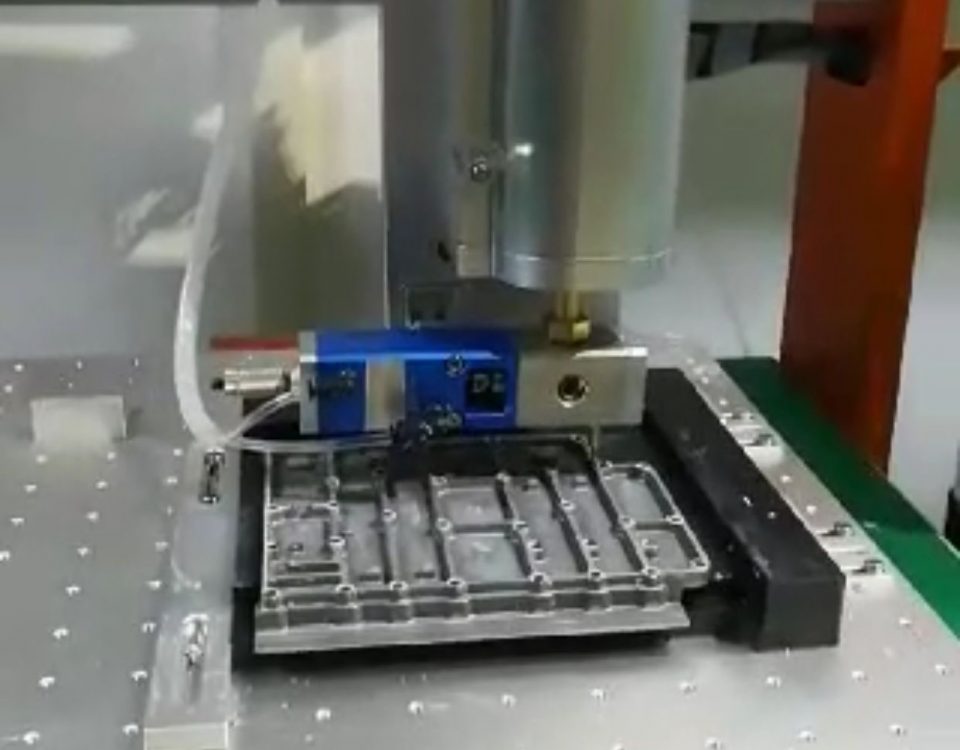

1、Die casting operator spray release agent change to automatic spray release agent

2、MES Propose make Pin position gauge to inspecting parts