Special Project with Multi-Masking Requirement

MES was award a new project earlier this year. This project had a high requirement of masking. Many places needed to be masked and no powder was allowed.

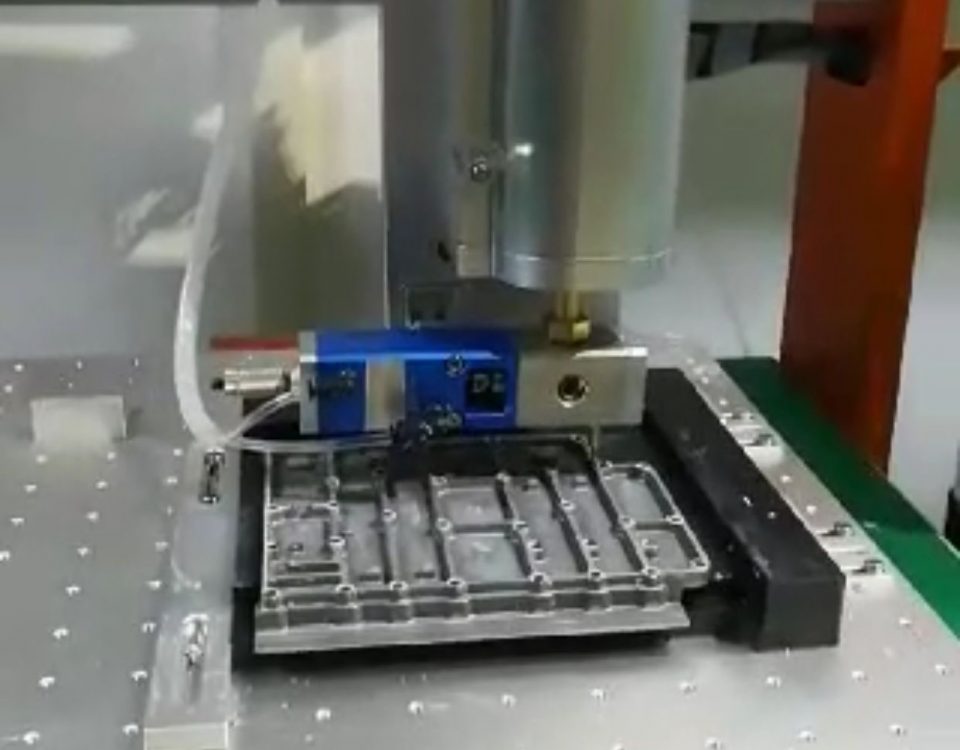

Due to the design of this product, its surface was uneven, and the edge was very narrow. If the supplier had used the conventional masking, which is tape, the output would have never met the customer’s requirement. The customer was struggling with this, yet they didn’t want to change the product design.

MES engineers carried out numerous experiments, and at last, they found the best solution, which was tape + silicone mold. The tape was used in a flat and big area, while the silicone was for a small and uneven place. Our engineers noticed that silicone hardness was a key in the test. If the silicone was too hard or too soft, it wouldn’t fit the part well enough to keep powder out. After repeated testing and improvement, MES solved the problem by altering the silicone hardness, adding ribs as well as keeping spaces.

Great job, everyone! We are so proud to have a dedicated and robust team!