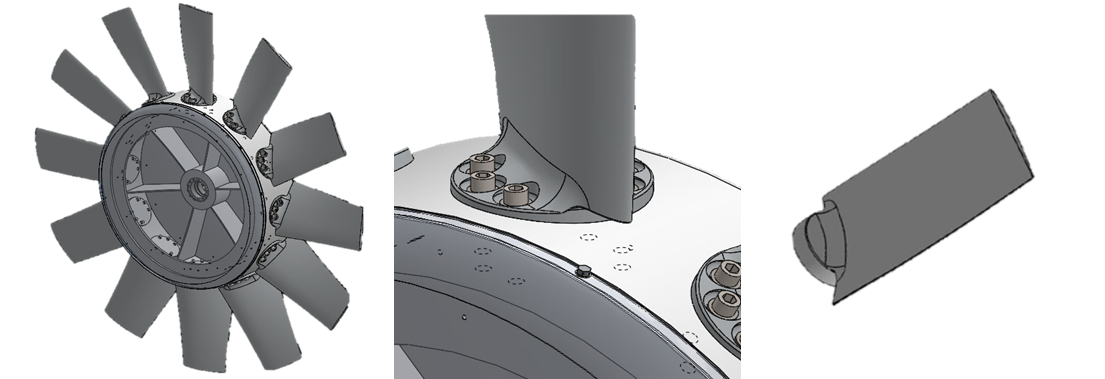

New Application: Impeller Blade Casting

MES was proud to deliver one of a kind impeller blade castings for Axial fans. Material was carefully chosen by the customer because of excellent strength properties at elevated temperatures. Aluminum C355 offers excellent castability, pressure tightness and resistance to hot cracking. C355 also boasts an excellent fluidity and solidification shrinkage tendencies. C355 also allows for excellent welding strengths although this application did not allow any welding. Polished finishes can be worthy of excellent engineered component which customers can see. These blades were designed and manufactured for Axial fans which are in-turn being used in underground and above-ground mining and power industry.

MES Inc. 非常荣幸的在上个季度推出了独一无二的轴流风机叶轮叶片铸件。铸件过程中温度的升高要求所用材料要有极佳的强度特性, 因此铸件原材料都是由客户慎重的考虑和挑选的。铝合金C355具有很强的铸造性,气密性和抵抗热裂纹的能力。同时它又具有极佳的流动性和凝固收缩倾向。C355可承受极大的焊接强度,尽管这个应用并不需要任何焊接。抛光处理对优质的工程零件是有价值的,因为客户可以看得到效果。这些叶片是为制作轴流风机而设计和生产的, 轴流风机则运用于地下,地面的开采和电力行业。

Material was cast using high vacuum melting casting furnace and high tilt automatic equipment. All parts were then X-ray tested per ASTM E155 with expectation to meet Level 2 near the shank of the blade and Level 4 in other areas. Parts also went through machining with tight tolerance of +/-0.02” expected near the shank of the blade. Parts were required to be heat treated (Tempered T-6) level to ensure mechanical properties and alleviate internal stresses. However, post quenching, some distortion was noticed along the blade twist angle and a special fixture was developed to ensure twist angle of blade. Tempering was then after Reshaping to relive the stress from quenching and reshaping. Reshaping, Quenching and Base Machining was done to ensure part twist characteristics were in-tact and tolerance requirements were met.

所有的材料都是由真空熔铸炉和高倾斜自动装置铸造。 铸造的零件之后都依照ASTM E155的标准拍摄射线照片, 旨在测试零件是否达到叶片轮轴附近达到2级,其他部分达到4级的标准。除了叶片轮轴部位,零件的其他部分也要被加工以达到紧密度容限符合+/-0.02”的要求。零件要求被热处理(温度 T-6)以确保它的机械性能和缓解内部压力。为了将零件弯曲成预期的限度,一种利用特殊装置叫做淬火的重塑技术被加入到热处理操作中。重塑之后回火来再次经历淬火和重塑产生的压力。重塑,淬火和基础加工被用于确保零件的扭转特性完整并且满足公差要求。

C355.0 can be sand cast or permanent cast. Typical Sand casting applications include printing press bedplates, air compressor pistons, water jackets, crankcases, electric motor fans and blowers. Permanent mold castings are developed for aircraft, missile, and other components requiring high strength, and for fittings, impellers, timing gears and aircraft supercharger covers. Automotive uses for this aluminum grade include passenger car wheels, engine blocks, cylinder heads, spring brackets, transmission cases, and miscellaneous truck and trailer castings.

C355.0可以沙铸也可以金属型铸造。 典型的沙铸应用包括印刷机底板,空气压缩机的活塞,水套,曲轴箱,电机风扇和鼓风机。金属型铸造多用于航空,导弹和有高强度要求的零件制造上;也被用来制造可拆除装置,叶轮,正时齿轮和飞机增压器盖。使用C355.0铝级的汽车应用包括:客车的车轮,发动机缸体,汽缸盖,弹簧支架和变速箱,以及各种各样的卡车和拖车的铸件。

Application Specifics:

应用特性:

Material – C355 with T6 heat treatment

材料-C355加上T6热处理

Cast Weight – 52 Lbs

铸造重量-52磅

Post-Machining Weight – 47 Lbs

后加工重量-47磅

Overall Length – 32.5”

总长-32.5英寸

Blade Length – 30.6”

叶片长度-30.6英寸

Porosity Requirements – Level-2 X-ray requirements with some areas allowed at Level-4

孔隙度要求-达到2级X射线要求,部分区域可接受4级标准

No distortions allowed along the trailing edge

机翼后缘不允许扭曲

Proper filling of the OD of Shank area

轮轴区域允许外径适当填充

Meeting Elongation requirement of 8% on such a long part while meeting T6 mechanical properties

达到8%的拉伸要求的同时满足T6的机械性能